From a Two-Man Enterprise to a Renowned German Company

Hawle Germany was founded in 1967 in Freilassing. The Hawle product portfolio has been constantly extended since then in close consultation with its German customers, and refined to suit their individual requirements. Today customers can enjoy numerous special solutions in addition to more than 500 products.

Our enterprise is deeply rooted in its birthplace in the Berchtesgaden region of Bavaria. Today Hawle with a workforce of approximately 270 numbers among the largest employers in the area, and has developed from being purely a manufacturer of fittings to an independent manufacturer and systems provider.

In order to satisfy the high standards of quality it expects of its products and services, the Hawle Group in Germany extended its activities by establishing Hawle Kunstoff GmbH (Hawle Plastics Ltd) in Wiehl and Hawle Service GmbH (Hawle Service Ltd) in Brühl to compliment the main plant in Freilassing and its own foundry in Fürstenwalde.

Owing to its successful market entry in 1967 and the continual search for new business segments, Hawle is able to offer its customers a large spectrum of customer-orientated services both today and in the future.

2022

Digital construction - BIM data

By introducing digital product data, Hawle Armaturen GmbH was able to offer yet another milestone in digital product service. From that point on, customers have been able to implement their construction projects using digital product data (BIM data) from Hawle, from the initial idea and planning through to the completed installation.

2020

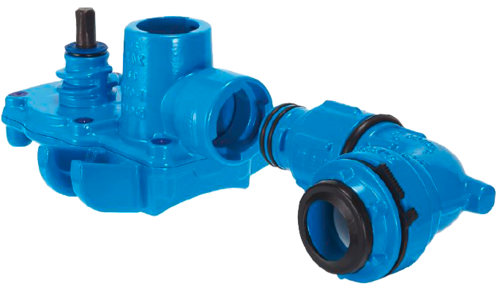

Hawle water meter shaft

The Hawle water meter shaft was developed specifically for installation on domestic water connections and is particularly suitable for new buildings or renovation projects. The Hawle water meter shaft can be used, for example, wherever access to buildings is restricted or simply impossible owing to the prevailing local conditions. This may well be the case, for instance, where there is a lack of cellar facilities or where the space available in the cellar does not permit the installation of a bracket for the water meter connection fittings.

In addition, the Hawle water meter fittings can be installed and removed quickly and hygienically thanks to their innovative connection technology.

2020

Hawle Heavy Duty Surface Box

Increased heavy goods traffic on busy roads can lead to high stress levels, which can cause the surface boxes installed there to subside. The reasons for this include a soft subsurface or open-pored asphalt, so-called silent asphalt. At high summer temperatures, the asphalt can soften further and sink due to these heavy loads. As a result, surface boxes laid in the road as a floating installation can also subside. The Hawle heavy-duty surface box was developed especially to prevent this problem.

Complex and cost-intensive maintenance measures are thus avoided. With the Hawle heavy-duty surface box, a form-fit load transfer takes place via the base plate. The surface box thus combines the advantages of rolled-in surface boxes with those of rigid models. The Hawle heavy-duty surface box is available in two versions: for gate valves and for control valves.

2020

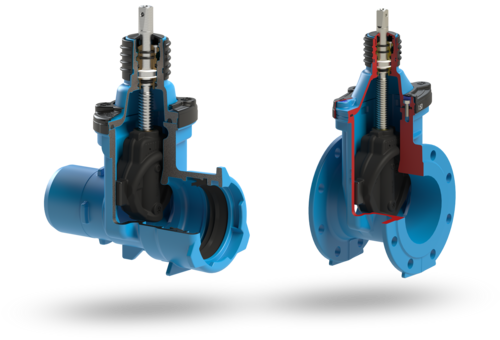

market launch of E3 gate valve

This revised, cutting-edge valve design will gradually replace the previous E2 valves. Originally, we planned to present them at IFAT in May 2020, but regrettably, the current health crisis forces us to do this presentation by email instead.

The tried and trusted E2 valve design has received a technological update, which resulted in the following improvements in E3 valve design:

- Wedge and wedge nut fully vulcanized

- Double bayonet O-ring carrier

- Duplex stainless steel spindle

- Extended and improved edge protection

2019

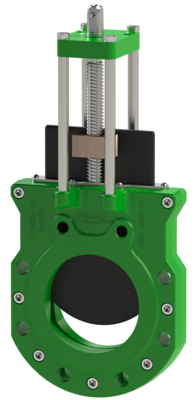

Market launch of HaPur® Knife Gate Valve

Aggressive wastewater in municipal sewage disposal systems always places high demands on the valves to be installed. This was the starting point for the development of a knife gate valve with a PUR-coated shut-off blade, which had to be particularly resistant to aggressive wastewater and chemicals. In 2019, the idea was made reality with the market launch of the HaPur® knife gate valve. The advantageous shut-off blade is scratch- and cut-resistant and thus offers a high level of operational reliability and resistance to aggressive wastewater and chemicals. Thanks to the hexagonal recesses for nuts, the gate valve can also be used later as an end fitting, e.g. for pipe renovation. The resilient-seated knife gate valve HaPUR® thus sets new standards in municipal wastewater disposal.

2018

Acquisition of shares of the company MIV d.d. / Croatia

With effect from 28.12.2018, Hawle Deutschland Beteiligung has taken over 89.18% of the shares of MIV d.d. Varaždin / Croatia. With this acquisition, synergies between all companies of the Hawle Germany group should be found and the position in south-east Europe plus additional export markets be strengthened.

2018

Presentation of the Digital Combination Air Valve

In order to be able to detect dangers and risks at an early stage, e.g. flooding of a manhole or the malfunctioning of a valve, a digital combination air valve (order no. 986-00) was developed. This combination air valve from Hawle makes it possible to monitor supply and disposal networks at any time of day or night in order to be able to take prompt action if necessary. This minimises the risk of damage and maximises operational safety.

2017

New administration building

The company’s continuous growth made it necessary to expand capacity in both the production and administration departments. Plans were developed to optimise the production area on the one hand and to create urgently needed office space on the other. The ground-breaking ceremony for the three construction phases took place in the spring of 2015. With the new building, Hawle Armaturen GmbH once again underlined its commitment to Germany as a production location.

2016

The Founding of the Hawle Service

With the founding of Hawle Service GmbH it was possible to create a wide range of customer-orientated services. Among others Hawle Service GmbH undertakes the inspection and maintenance of all brands of fittings for gas and water distribution facilities including hydrants, isolation valves, pressure-reducing valves, shaft fittings and air release valves as stipulated in the regulations of the German Association for Gas and Water (Deutscher Verein des Gas- und Wasserfaches). The extensive range of services is complimented by work relating to house service connection such as the changing of a gas or water meter, or maintaining gas pressure regulators.

2015

The founding of Hawle Kunststoff

With the help of Hawle Kunststoff GmbH, it was possible to gain a foothold in a new niche market. Since then, customers have had the opportunity to purchase innovative and flexible chamber systems in combination with pre-installed Hawle fittings. These sustainable complete solutions are characterised by a high degree of prefabrication and save time-consuming installation work in the construction pit.

2013

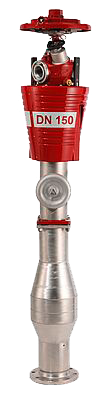

Market Launch of the Standpost Hydrant R1

An enquiry made by Fraport AG (Frankfurt Airport Services Worldwide) inspired a further innovation. Integrated hydrants had always posed a problem for staff. Hawle quality was called for since they had been entirely satisfied with the H4 DN 100 hydrant. Hawle was quick to recognise that although the normal shut-off principle could be transferred to DN 150, no advantages were to be gained over the standard design. The goal of reducing torque to a minimum could best be achieved with a ring cylinder since the pressurised surfaces are much smaller compared to those of a piston.

2012

A New Warehouse Facility

In 2012 Hawle established the basis for further growth by adding a new warehouse to the company premises. The warehouse was constructed on the former football pitch, and a photovoltaic system installed on its roof. The total annual output is approximately XXXXXX kWh, which are either consumed by the company or fed into the local grid. By building the new warehouse Hawle has been able to improve the rate of its stock turnover and offer its customers an even faster delivery time.

2007

Mourning for the Founder Heinz Engelbert Hawle

The demise of the former founder of Hawle Freilassing - Heinz Engelbert Hawle – overshadowed the following year despite the market launch of the K3 gate valve.

2007

Hawle in Existence for 40 Years

Fourteen sales representatives, 220 employees at the Freilassing site and 220 employees in Fürstenwalde ensured an upward trend in sales performance.

Similarly, nothing stood in the way of an orientation towards the transatlantic market when H-TEC was founded in the USA and promised positive dividends. The demands of the American market with its individual standards were satisfied henceforward by the employees residing there with the support of their German colleagues

2003

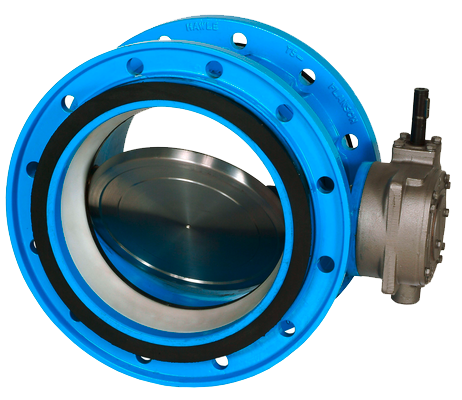

Market Launch of the Hawle PRO Butterfly Valve

In 2003 attention focused on the problem of standard valves. Their weak point was considered above all to be the seal clamped on the valve disc. As this was not possible without tension the seal gradually moved outwards over the years resulting in an increased torque. In extreme cases this even caused the seal to be sheared off.

The inclusion and steel reinforcement of the seal in the housing of the engineered PRO butterfly valve provides the appropriate solution and form stability. The seal is pressed onto the disc depending on the pressure, and is free of restraint.

2001

Invention of Roller Diaphragm Technology for Air Release Valves

Just one year later air release valves intensified competition with a further innovation. The invention of these valves in the sewage sector was triggered by the need to incorporate Hawle corrosion protection and quality standards into this particular area. Up until then the enterprise had sold appropriate valves as merchandise or installed these in sewage fittings they had expressly developed. The roller diaphragm (the first prototype was a bicycle inner tube) provided a venting capacity for operation and refilling. The membrane opens in accordance with the volume of air accumulating (proportional). The same principle was later implemented in the HAVENT.

2000

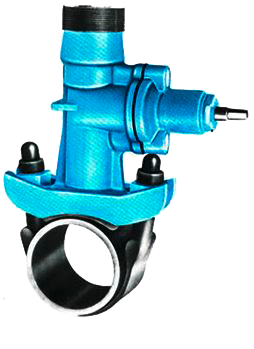

Market Launch of the Milling Valve

Opportunities for expansion and new markets were constantly explored. With the founding of the Rumanian subsidiary it was possible to further increase international awareness of Hawle products. Since then on-site contacts co-operating with colleagues from Germany have provided an impeccable service and offered appropriate advice.

Opening up this new market was not the only sensation of the year 2000. With the invention of the milling valve Hawle was able to overcome the drawbacks of standard valves and defy their otherwise very high rotational speed, high construction and poor corrosion resistance. All this was achieved by a feed nut with multi-start thread.

An expansion of a different kind took place in the same year when the petrol station in Freilassing commenced operations. When the former leaseholder of the petrol station retired Hawle decided to continue this line of business independently. The project boomed and generated encouraging profits.

1997

Hawle in Existence for 30 Years

Continuous growth was reflected in the number of employees at the Freilassing plant. At this stage a total of 10 sales representatives and a further 140 staff were holding the fort in production or administration at this branch.

1996

Laying New Foundations: Reconstruction of our Foundry in Fürstenwalde

Just one year after its purchase plans were already afoot to demolish the outdated foundry complex and to reconstruct it on the same site. The project ran from 01.10.1996 to 09.09.1997. In September 1997 the old foundry was decommissioned.

1995

Purchasing the Foundry in Fürstenwalde

The year 1995 was not only crowned by the market launch of the ZAK system but also by another event. In order to guarantee optimum product quality at the departure point in the value-added chain, entrepreneurs decided to purchase the foundry Duktil Guss in Fürstenwalde (Brandenburg). The founders had been relishing the purchase of a foundry for a long time, and a mere 5 days before the necessary declaration of insolvency, they signed the purchase agreement having been totally won over by the German site.

At the time it was a very unusual step fraught with risk, but looking ahead a good one. With the acquisition Hawle secured a total of 75 jobs in Germany. Nothing stood in the way to prevent it from collaborating smoothly with the castings suppliers now its own. Prior to the purchase Hawle had never sourced any cast parts from this company.

1995

Markteinführung Hawle ZAK-System

Ein ereignisreiches Jahr folgte 1995. Mit der Markteinführung des ZAK-Systems wurde zusammen mit dem bereits bestehenden BAIO-System ein durchgängiges gewindeloses Verbindungssystem geschaffen. Auslöser für die Kontsruktion des ZAK-Systems war u. a. die Möglichkeit der Inkrustierung und Korrodierung. Bei derartigen gehanften Gewindeverbindungen gibt es immer unbeschichtete Bereiche, die korrodieren oder (häufiger) je nach Wasserbeschaffenheit inkrustieren können. Zudem sind gehanfte Verbindungen sehr zeitaufwändig und das Ergebnis vom Geschick des Monteurs abhängig. Erster Meilenstein in die richtige Richtung war die Doppel-O-Ringverbindung. Nach weiteren Ideen wie z. B. Korrosionsschutzringe lösten sich Hawle‘s Spezialisten vollständig vom stets blanken Gewinde und schafften ein Bajonettsystem. Kennzeichnend für dieses Verbindungssystem ist der durchgehende Korrosionsschutz.

1993

Market Launch of the Exchange Gate Valve

As the original Hawle invention the exchange flange quickly paved the way from conduit to gate valve. Initially installed primarily in the ground, it became increasingly prevalent in plants. Adjacent valves and pipeline components, however, were not always able to perform the function of tensile strength, or this ceased temporarily as a result of subsequent reconstruction. The problem of ensuring tension was solved by the development of the exchange gate valve with guaranteed tensile strength and integrated tensile strength in the flanges. In this respect, the customer no longer needed to worry about adjacent construction components.

1989

The Founding of Hawle Hungary

Nudged by Hawle Austria, the go-ahead was given in 1989 for Hungary. Hawle Austria, Hawle Germany and the municipal utilities in Budapest all had an equal share of the enterprise. Later the municipal utilities sold their share in equal measure to both Hawle enterprises and the company moved from Budapest to its current location in Szentendre.

1987

Market Launch of the Freeflow Underground Hydrant

Meanwhile 5 sales representatives and 68 staff members were employed by Hawle in Freilassing in production and administration.

It was this team of men and women who succeeded in 1987 in launching the freeflow underground hydrant onto the market as a brand new innovation. In particular the underground hydrant was to meet the demands of a robust isolating system as common hydrants were hitherto very sensitive to stones in the network. Attempts were also made to transfer the advantages of the meanwhile proven Hawlinger, especially its unobstructed flow. In the end Hawle developed a freeflow underground hydrant whose features continue to influence today’s market; it offers high flow rates, is robust due to a shut-off blade, is settable retroactively and provides access for measuring probes and pigs.

1986

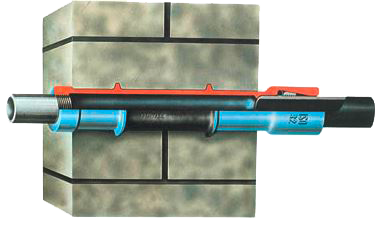

Market Launch of the Fast-Construction Wall Duct

Three years later saw the next significant new development. Up until then it had been usual practise to install wet wall ducts; that is to say, using mortar. This design was hindered by the enormous amount of time required for the mortar to set and the care or skill needed by the installation team. Since the technology used for drilling the core hole had become simplified, the idea arose of developing a dry mortarless construction.

In this invention the core hole was not created until the cellar had been completed, which meant that any amendments to the planning could be incorporated and the house connections room ideally designed. Together with technology developed by the municipal utilities in Ulm, which enabled all core holes for various areas to be drilled in one go, this new innovation from Hawle, the so-called fast-construction wall duct, greatly facilitated work in this sector.

In the same year Hawle invested in a sector outside the industry. The petrol station was purchased (property in the south). The reason for this unusual purchase was the imminent sale of the petrol station site and the area of today’s warehouse for outgoing goods. The intention was to counteract a tall, unattractive and obtrusive building. In order to cover the costs incurred, one of the green areas at the rear had to be sold. Hawle let the petrol station. Today the site of the former petrol station is home to the new administrative building which opened for business in 2017.

1983

Market Launch of the Flangeless Valve and Pipe Fittings Programme “BAIO®-System“

For a long time only flange valves and pipes were available, which had the disadvantage of inflexible connections and no chance of being stress-free.

That was not all. The time-consuming assembly, the large number of necessary parts and the corrosion affecting the screws used at that time were other weaknesses which needed addressing.

Interest in pipes was focused primarily on the spigot and socket joints available (the TYTON spigot at that time was not secured against tensile stress). These were not only easy to assemble but also provided a stress-free, flexible connection.

It was this simplicity which won over Hawle’s specialists and generated the idea of developing a similar system for valves. As the connections had to have high tensile strength from the outset, this problem was solved by using a robust bayonet joint which was simple and quick to install.

1981

Relocation to Freilassing

The entrepreneurs were faced with yet another difficult decision in 1981 when a lack of space at the Ainring site necessitated a further building extension. Finally the decision was taken to construct a new building in Freilassing. A return to Freilassing had not been the original wish or intention as Mr Fach would have liked to erect the building in Mitterfelden again. In the end the goodwill shown by the town of Freilassing captivated all concerned and Hawle employees went about their business in the place of their original roots. The first part of the building, which still exists today, had found its place.

1979

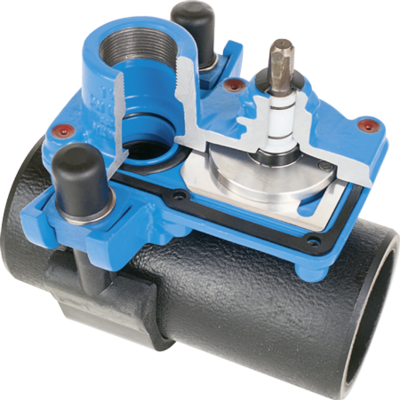

Invention of the "Hawlinger" Pipe Drilling Saddle

More staff imply a greater capacity for inventions and new developments. The wish arose for a robust house connection valve which would fulfil the demands of a long functional life particularly when not in operation for long periods. Up until then no competitor product had been able to achieve this nor satisfy the need for free flow to avoid exposing the valves to long supply disruptions even when pressurised. With the invention of the Hawlinger pipe drilling saddle in 1979 Hawle was able to fulfil this customer request.

1977

Three Additional Sales Representatives

The one sales representative was not to remain alone for long. Just two years later the enterprise announced three additional sales representatives. A total of four men now travelled directly to the customer offering both technical and practical assistance and advice. The Ainring site was also constantly undergoing expansion. The enterprise now employed 22 people.

1975

The First Sales Representative

Faster and closer to the customer – the two founders advanced towards this goal when they employed the first sales representative in 1975.

1973

Fully Vulcanised Strap

At an early stage Hawle specialists gave much thought to established products based on outdated technology. Their aim was for products which were more efficient, easier to use and of higher quality – a process which has not stopped even today.

This led to innovations in 1973. For a long time U-bolts and flat steel straps had offered the best available solution for installing pipe drilling saddles and valve saddles. As technology progressed a fully vulcanised strap was developed which solved all the difficulties which had occurred during the first few years. This was a flexible component which adapted perfectly to the pipe contours. This feature coupled with the width of the strap enabled the tension impacting on the pipe to be reduced. Furthermore, the rubber casing helped to reduce tension while at the same time providing optimum corrosion protection.

1971

Relocation to Ainring

Space and capacity constraints at the Freilassing site rendered it inevitable in the year 1971 to construct a larger administrative and production building, and to sell the plot in Freilassing. A generous building plot offered itself at this time in the neighbouring community of Mitterfelden (Gewerbestraße 1). The space gained was large enough to lease a part of it to Atomic.

Despite the work involved in relocating developments did not stand still. That same year the employees’ industry was rewarded when the universal saddle system was launched onto the market.

1969

Entry to the Swiss Market

In 1969 Heinz Hawle had the centre of his life in Switzerland. This ultimately led him to open the doors of both Hawle enterprises to the Swiss market also. The fitters and water supply companies there at that time were quick to recognise the quality of the blue Hawle fittings. The corrosion-resistant surface coating particularly impressed, and consequently facilitated the introduction of the products. In order to better satisfy both the specific national standards and trade practices, he placed his trust in founding an independent enterprise, namely Hawle Armaturen AG (Hawle Fittings PLC) in Sirnach and the parts production there.

1967

Founding

Mr Engelbert Hawle junior, did not wish to let this chance slip and as a result collaborated with Mr. Hans Fach to found the limited partnership E Hawle KG on 10 April 1967 in the railway town of Freilassing. Every beginning is hard so the two newcomers used the existing range of Austrian products and tried initially to master and expand their distribution within Germany.

It soon became clear that it would be unavoidably necessary to adapt to German requirements if the enterprise were to develop further. The starting signal for in-house production and independent development activities had been given.

From now on in their own production hall existing products were tailored to suit customer demands, house connection valves were produced for the first time and experiments on in-house developments undertaken.