-

Version for sewage water and gas on request.

-

Other accessories on request.

207-02

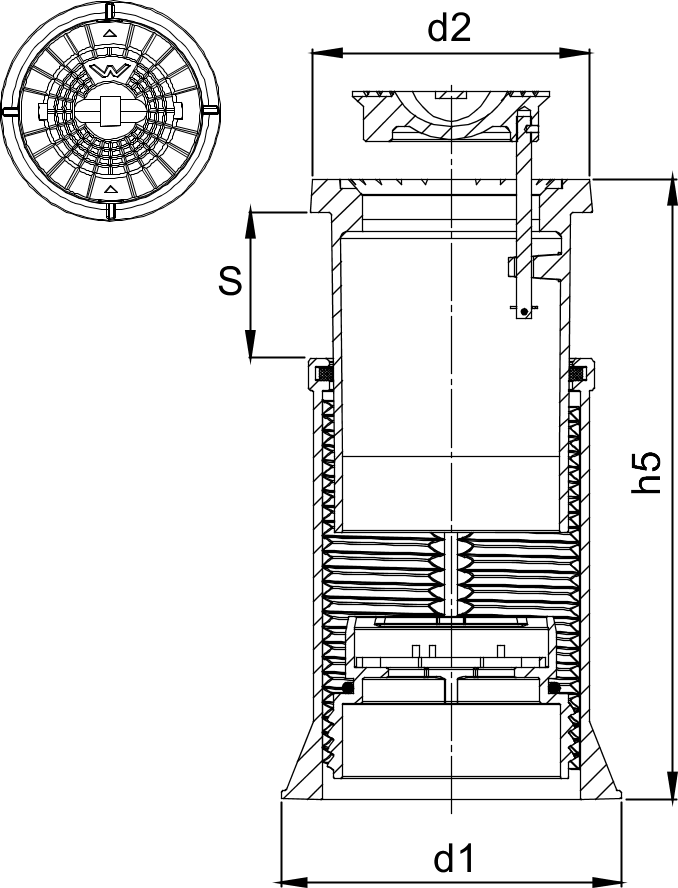

Heavy-duty surface box for gate valve

| Material: |

Cover: GJS-400, Hawle epoxy powder-coated Threaded ring: GJS-400, Hawle epoxy powder-coated Drawing ring: GJS-400, bituminized Base box: GJS-400, bituminized Positioning pin: stainless steel |

|---|---|

| Medium | Water / Gas / Sewage |

The Hawle heavy-duty surface box for gate valve is to be used for installation in bituminous traffic areas exposed to high loads. The drawing ring of the heavy-duty surface box permits a large adjusting range of 22 cm at most.

During rolling in a bond is created between the drawing ring and the asphalt layer. Due to the integrated threaded ring which can be individually adjusted on site, a form-locked connection is established between the drawing ring and the threaded ring. Thus, the load can be transferred from the drawing ring to the threaded ring. Subsequently, the traffic load is distributed to the base box via the threaded connection of the threaded ring and the base box. Therefore, the load is evenly transferred to the base plate and then discharged into the subgrade of the road. Thus, the surface box combines the advantages of boxes for rolling in with those of rigid surface boxes.

Moreover, the slanted seat at the cover and the box reduces the rattling tendency of the cover compared to conventional surface boxes.

The cover is powder-coated to avoid contact corrosion between the cover and the box, on the one hand, and to ensure that the cover can be loosened easily, on the other hand.

The cover is connected to the box via a positioning pin with a cotter and a shim.

The drawing ring is provided with a directional arrow.

Size: following DIN 4056

For turning the threaded ring, an adjusting tool (597-02) has been developed which can be ordered separately.

|

Order Nr.

|

d 1 |

d 2 |

h5 |

Cover inscription |

Description |

S max. |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|---|---|---|

|

2079000000

|

270 mm | 220 mm | 380 - 600 mm | W | Cap complete | 0 mm - 220 mm | 40,00 kg |

|

Operating instructions

|

|---|

| Operating and maintenance instructions - Heavy-Duty Surface Box for Valves and Gate Valves |

|

Article Nr.

|

Product description |

|---|---|

| 204-00 | Universal base plate for surface boxes for gate valves and valves |

| 204-02 | Base plate of concrete for surface boxes for gate valves |