-

Drop jacket available with individual inscription - price on request.

-

Hydrant head possible in any desired RAL colour on request

517-00

Above ground hydrant of stainless steel with drop jacket, break-away type

| Material: |

Drop jacket: robust, UV resistant plastic Standpipe: thick-walled stainless steel tube with a Hawle epoxy powder coated up to the pre-determined breaking point Valve rod/spindle: stainless steel Valve body: stainless steel |

|---|---|

| Max. operating Pressure: | Potable water: 16 bar |

| Medium | Water |

Hawle above ground hydrants are made exclusively of high-grade and non-corroding materials. The choice of materials ensures high functionality and consistently good appearance in all environmental situations (salt spreading, industrial areas, coastal regions).

The "drop jacket technology" protects the upper outlets from unauthorized access. The two individually lockable outlets B can be opened only after the drop jacket is unlocked and drops downward.

The predetermined breaking point ensures that the closed hydrant remains tightly sealed in case of an accident. Spare screws for quick repair are accommodated below the drop jacket. The spare screws shall be tightened at a maximum torque of 60 Nm (use of a torque wrench). According to DVGW VP 325 the hydrant shall be installed such that the predetermined breaking point is situated approx. 120 mm (+ - 80) above ground level.

Moreover, there are some advantages in case of storage, transportation and installation. The materials used have a comparably much lower weight than conventional above ground hydrants of DCI.

For all Hawle above ground hydrants the flow rate at a differential pressure of 1 bar is above the value specified.

Hydrant head: red, RAL 3003

Fixed couplings: 2 x B

Standpipe: alternatively with fixed coupling A

Outlet: flange

Defined stop on opening and closing

Drain-off system:

CE marking

|

Order Nr.

|

DN |

Operating pressure max. |

Pipe cover depth |

Outlet A |

Outlet B |

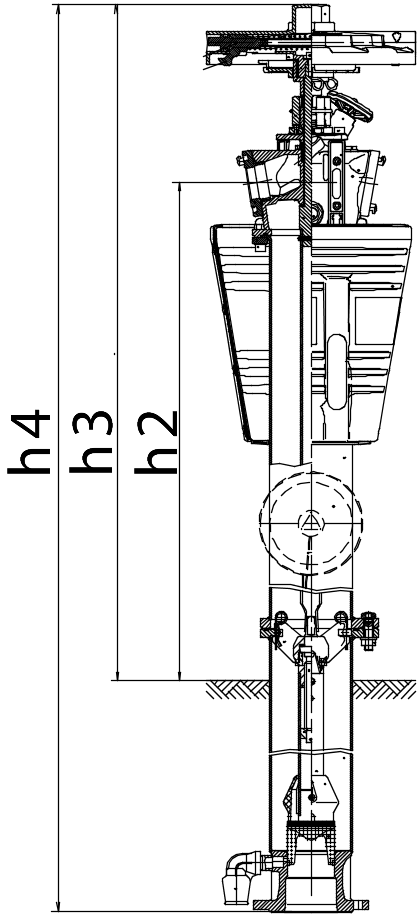

h2 |

h3 |

h4 |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

5171001000

|

100 | Potable water: 16 bar | 1,00 | 1 | 2 | 952 mm | 1292 mm | 2164 mm | 73,00 kg | |||

|

5171001250

|

100 | Potable water: 16 bar | 1,25 | 1 | 2 | 952 mm | 1292 mm | 2414 mm | 79,00 kg | |||

|

5171001500

|

100 | Potable water: 16 bar | 1,50 | 1 | 2 | 952 mm | 1292 mm | 2664 mm | 84,00 kg | |||

|

5171001501

|

100 | Potable water: 16 bar | 1,50 | - | 2 | 952 mm | 1292 mm | 2664 mm | 79,00 kg |

|

Further information

|

|---|

| General instruction for Hydrants |

|

Technical Documents

|

|---|

| partlist---above-ground-hydrant-of-stainless-steel-with-drop-517-00_2 |

|

Operating instructions

|

|---|

| Operating and maintenance instructions - Above ground hydrant |