- 1)

985-01

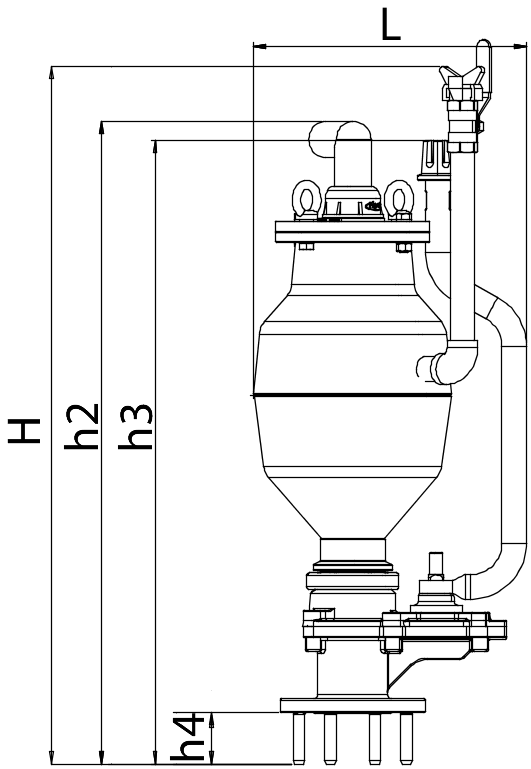

Air valve with shut-off unit

| Material: |

Air valve housing: Steel with Hawle epoxy powder coating or alternatively stainless steel Float rod/ spring: stainless steel Float ball: POM outlet elbow: PE 100 with stainless steel strainer Shut-off unit: GJS 400 with Hawle epoxy powder coating, stainless steel shut-off blade Key pipe: stainless steel |

|---|---|

| Max. operating Pressure: | Wastewater: 16 bar |

| Medium | Sewage |

The air valve with shut-off unit consists of the air valve type 986-00 with spigot end that is locked in the integrated shut-off unit by means of a quick lock (bayonet). The shut-off unit is opened and closed with the key pipe. The key pipe also serves as twist lock device for the air valve. The air valve with unique roll-on membrane technology is best suited for the venting of large amounts of air under operating pressure. The valve seat does not get in contact with the medium. The air valve operates continuously from 0 to 16 bar, perfectly sealing even when unpressurized. The sealing principle with roll-on membrane has a shock-absorbing effect. The air valve is provided with a flushing connection. By connecting a flushing line, dirt can be flushed out of the air valve easily and quickly. In case of major dirt, the interiors have to be dismantled, cleaned and re-installed. Please note: Air valves contain compressed air. Prior to any maintenance work air valves should be put out of operation and depressurized via the ball valve! Max. air release capacity: 440 Nm³/h Operating range: 0 – 16 bar Lower outlet: Flange DN 80 (EN 1092-2)

with threaded bolt (70 mm) alternately also available with internal thread 2”

Following special functions on

request:

- Only air release

- Only air intake

- Air release stop: for lines purged with compressed air

For further information please refer to the "Technical description".

|

Order Nr.

|

Connection |

L |

H |

h2 |

h3 |

h4 |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|---|---|---|

|

9851809904

|

Flange DN 80 | 376 mm | 961 mm | 886 mm | 860 mm | 71 mm | 42,70 kg |

-

version with stainless steel air release valve body on request

-

Connection: flange DN 80 (EN 1092-2) with threaded pin (70 mm)

-

Surcharge for only air intake or release Ord. No. 986 002 9901 on request.

-

Outlet elbow with male thread (AG) 1 1/2” Ord. No. 986 400 0155

|

Article Nr.

|

Product description |

|---|---|

| 986-01 | Air release stop for air valve „986-00“, "989-00", "989-01" and air valve set "985-00" |

| 986-02 | Indicator plate |

| 986-03 | Exhaust air kit with hose for air valve 985-01, 986-00, 989-01 |